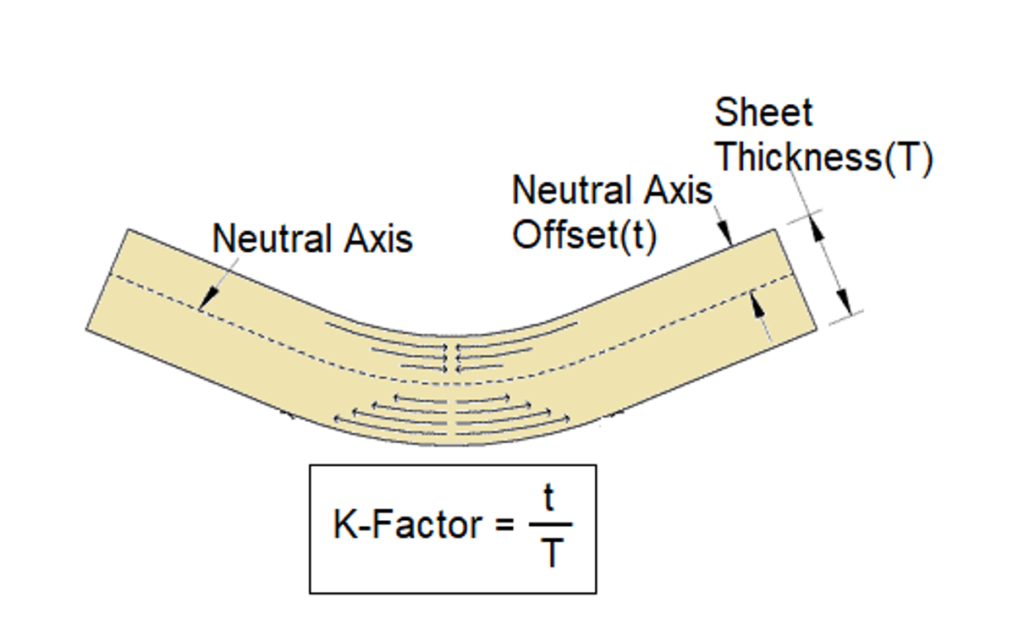

Sheet Metal K Factor - When metal is bent the top section is going to undergo compression and the bottom section will be stretched. The formula to calculate the k factor is: Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Web based on the given information:

Web based on the given information: Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. When metal is bent the top section is going to undergo compression and the bottom section will be stretched. The formula to calculate the k factor is:

The formula to calculate the k factor is: Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. When metal is bent the top section is going to undergo compression and the bottom section will be stretched. Web based on the given information:

what is the correct value of K factor in sheet metal in solidworks

Web based on the given information: Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. When metal is bent the top section is going to undergo compression and the.

Sheet Metal KFactor (What it is & How to Measure) YouTube

Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. The formula to calculate the k factor is: Web based on the given information: Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. When metal is bent the top.

KFactor Sheet Metal

Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. The formula to calculate the k factor is: Web based on the given information: When metal is bent the top section is going to undergo compression and the bottom section will be stretched. Mathematically k factor value is.

The Art And Science Of Bending Sheet Metal Hackaday

When metal is bent the top section is going to undergo compression and the bottom section will be stretched. The formula to calculate the k factor is: Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. Web based on the given information: Mathematically k factor value is.

K Factors Bending Information Sheet Metal Industries

Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. The formula to calculate the k factor is: Web based on the given information: Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. When metal is bent the top.

Analyzing the kfactor in sheet metal bending

Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. The formula to calculate the k factor is: Web based on the given information: When metal is bent the top.

Sheet Metal K Factor (with Calculator and Formula)

Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. Web based on the given information: When metal is bent the top section is going to undergo compression and the bottom section will be stretched. Mathematically k factor value is equal to the ratio of position of the.

Stainless Steel Sheet Metal Gauge Thickness Chart Pdf Iweky

Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. When metal is bent the top section is going to undergo compression and the bottom section will be stretched. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. The.

What Is K Factor In Heat Transfer Design Talk

When metal is bent the top section is going to undergo compression and the bottom section will be stretched. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Web based on the given information: Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend.

Analyzing the kfactor in sheet metal bending Part II

When metal is bent the top section is going to undergo compression and the bottom section will be stretched. Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Web.

When Metal Is Bent The Top Section Is Going To Undergo Compression And The Bottom Section Will Be Stretched.

Web based on the given information: Sheet metal thickness t = 1mm bend angle a = 90° bend radius r = 1mm bend allowance factor ba = 2.1mm. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. The formula to calculate the k factor is: